Description

Straight Tuck End Boxes: A Reliable and Versatile Packaging Solution

Introduction

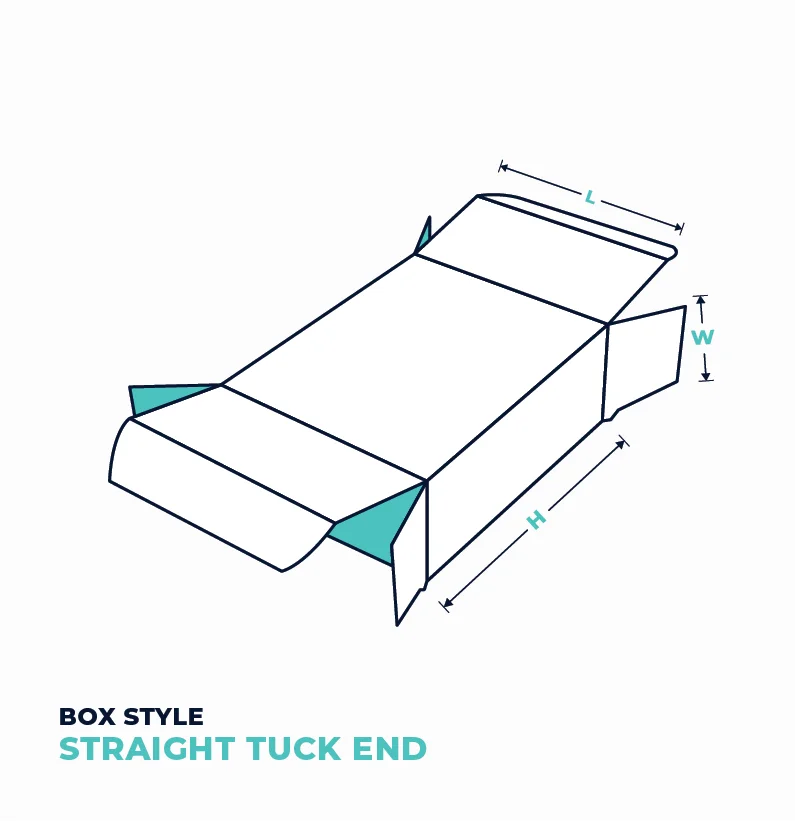

Straight tuck end boxes are a widely used and versatile packaging solution in the retail industry. Known for their simple yet effective design, these boxes provide a secure and professional packaging option for a variety of products. The defining feature of straight tuck end boxes is that both top and bottom flaps close on the same side of the box, ensuring a seamless and uniform appearance. Their ease of assembly, structural integrity, and adaptability make them a preferred choice for businesses looking for reliable packaging.

Structure and Design

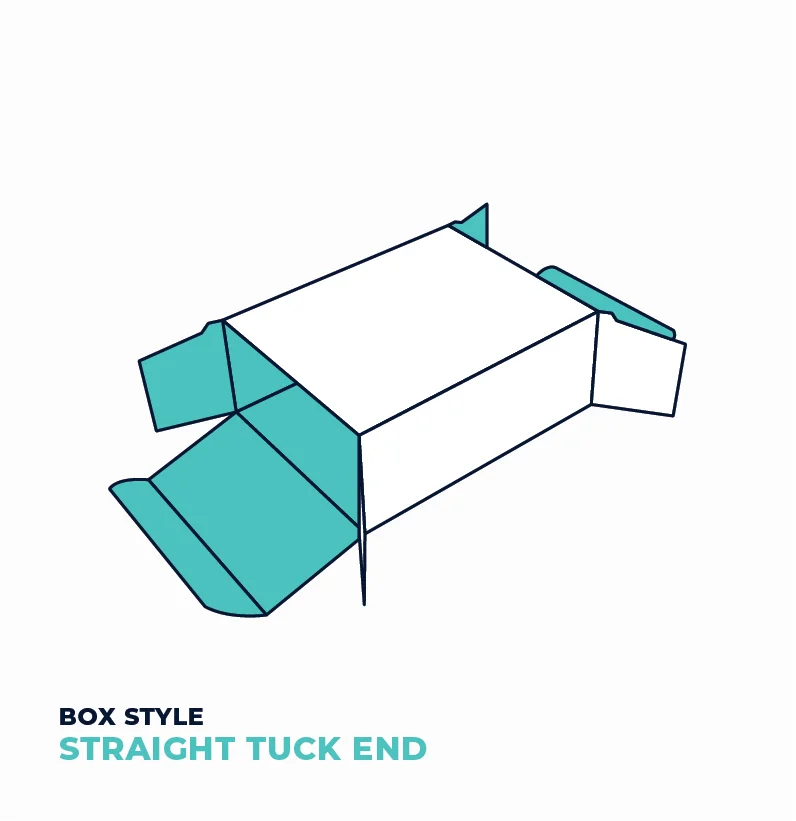

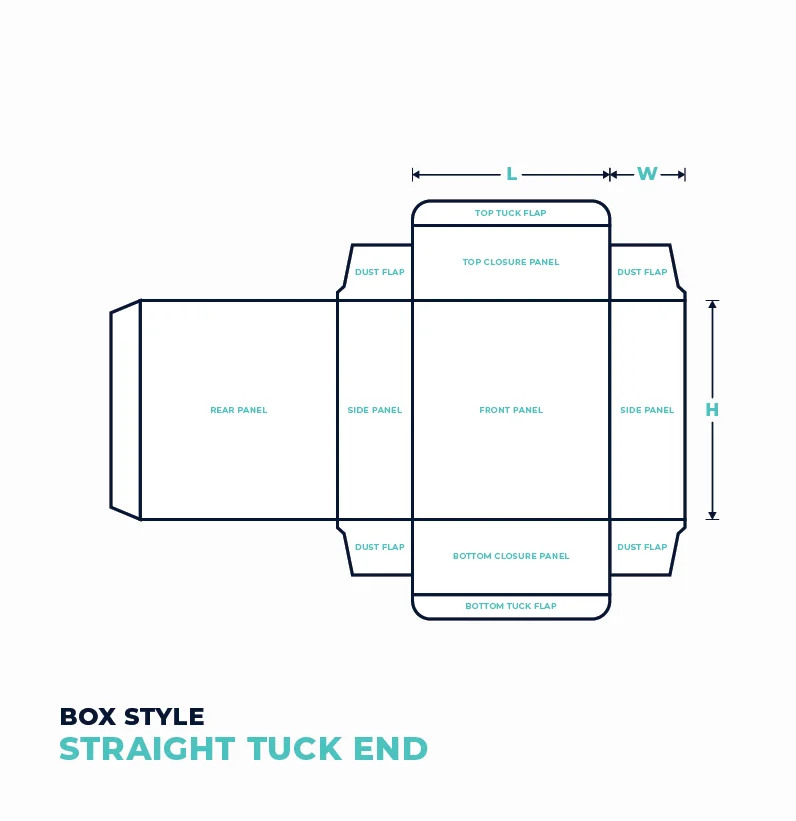

Straight tuck end boxes feature a straightforward yet efficient design that enhances usability and product security. Some key structural attributes include:

- Straight Tuck Closure – The top and bottom flaps fold and tuck into the same side, creating a clean and smooth finish.

- Pre-Scored Folding Lines – These make assembly quick and hassle-free.

- Flat-Shipped and Space-Saving – The boxes are delivered in a flat form, reducing shipping and storage costs.

- Customizable Size and Shape – Available in various dimensions to accommodate different product types.

Their simple yet effective design allows for easy packaging while maintaining a sleek and professional presentation.

Material Composition

Straight tuck end boxes can be crafted from a range of materials depending on the required durability and product type. Common materials include:

- Cardstock – A lightweight and cost-effective option ideal for smaller retail products.

- Kraft Paper – An eco-friendly and recyclable material for brands that prioritize sustainability.

- Corrugated Board – Provides added protection for fragile or heavier items.

- Rigid Paperboard – A premium option that enhances the visual appeal of high-end products.

The choice of material allows businesses to tailor their packaging to meet their branding and product protection needs.

Customization Options

Straight tuck end boxes offer a variety of customization options to enhance brand visibility and customer engagement. These include:

- Printing Techniques – High-quality offset, digital, or screen printing for vibrant logos and product information.

- Color and Graphics – Custom colors and branding elements to align with marketing strategies.

- Die-Cut Windows – Allows customers to see the product inside without opening the box.

- Embossing and Foil Stamping – Adds a luxurious touch to premium packaging.

- Glossy, Matte, or UV Coatings – Enhances durability and visual appeal.

- Custom Inserts – Provides additional protection and organization for packaged products.

These customization options make straight tuck end boxes an effective marketing tool, elevating brand recognition and product appeal.

Benefits of Straight Tuck End Boxes

- Easy to Assemble – The pre-scored folding lines allow for quick setup without additional adhesives.

- Secure and Functional – The straight tuck closure provides a firm seal to protect products.

- Lightweight and Space-Saving – Reduces shipping costs while ensuring durability.

- Eco-Friendly Options – Available in sustainable and biodegradable materials.

- Versatile Usage – Suitable for a wide range of industries and products.

- Professional Presentation – Clean and seamless design enhances product visibility.

- Cost-Effective – A budget-friendly packaging solution without compromising quality.

Industries That Use Straight Tuck End Boxes

Straight tuck end boxes are a popular packaging choice across various industries due to their adaptability and effectiveness. Common applications include:

- Retail Packaging – Used for cosmetics, electronics, and personal care products.

- Food and Beverage – Ideal for tea, chocolates, and confectionery packaging.

- Pharmaceuticals – Suitable for medicine bottles, supplements, and medical kits.

- Cosmetics and Beauty Products – Commonly used for skincare, makeup, and perfumes.

- Stationery and Office Supplies – Perfect for pens, notebooks, and office accessories.

- Gift and Promotional Packaging – Used for event giveaways and branded merchandise.

Conclusion

Straight tuck end boxes provide a practical, cost-effective, and customizable packaging solution for businesses across various industries. Their efficient design, ease of assembly, and structural integrity make them an excellent choice for secure and professional product packaging. With a wide range of customization options, these boxes not only protect the product but also enhance brand identity and customer experience. Whether used for retail, cosmetics, pharmaceuticals, or food items, straight tuck end boxes offer a reliable and visually appealing packaging solution.